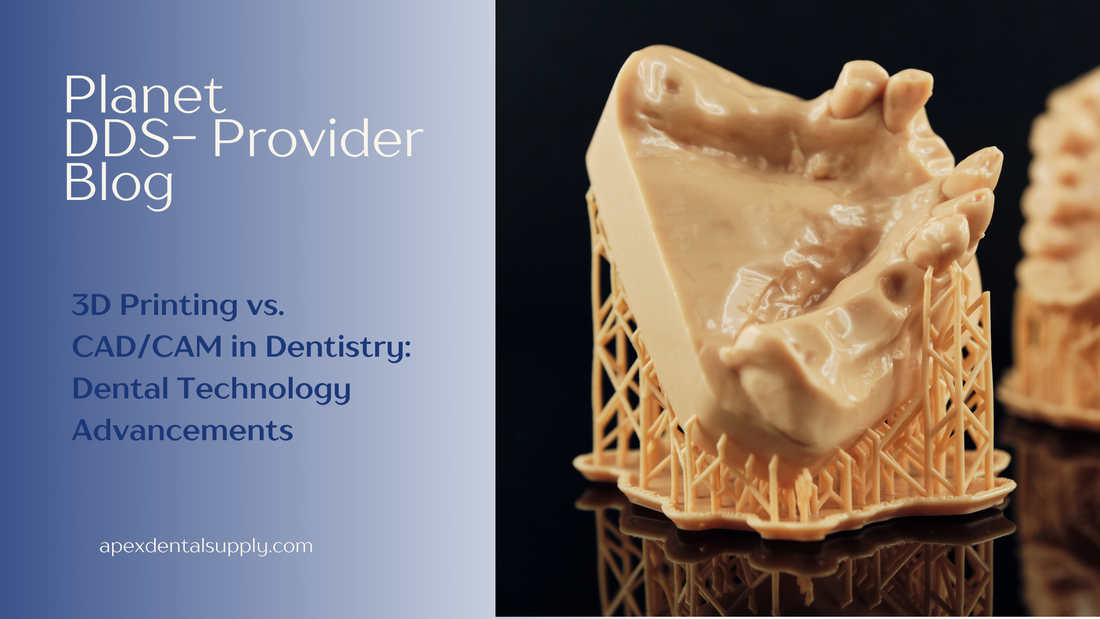

In the ever-evolving landscape of dentistry,dental technology advancements have played a pivotal role in reshaping the way dental professionals approach patient care and manufacturing processes. Two significant technologies, 3D printing and Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM), have emerged as transformative tools in the dental field. In this blog post, we explore the applications, benefits, and distinctions between 3D printing and CAD/CAM in dentistry.

3D Printing in Dentistry:

1. Digital Models and Impressions:

- 3D printing allows for the creation of highly accurate digital models and impressions of a patient's oral anatomy.

- This eliminates the need for traditional, often uncomfortable, physical impressions, improving the patient experience.

2. Custom Prosthetics and Restorations:

- Dental laboratories leverage 3D printing to produce custom crowns, bridges, and prosthetics with unparalleled precision.

- The ability to create intricate and patient-specific designs contributes to better functional and aesthetic outcomes.

3. Surgical Guides:

- 3D-printed surgical guides aid in precise implant placement during oral surgeries.

- This technology enhances the accuracy of procedures and reduces the risk of complications.

4. Material Variety:

- Dentists can choose from a range of biocompatible materials for 3D printing, including resin-based and metal options.

- This versatility ensures compatibility with various dental applications.

CAD/CAM in Dentistry:

1. Digital Design and Modeling:

- CAD is utilized for the digital design of dental prosthetics and restorations.

- Dental professionals can create detailed 3D models, allowing for meticulous planning and customization.

2. In-House Milling:

- CAD/CAM systems often include milling machines that enable in-house fabrication of restorations.

- This on-site capability reduces turnaround times and enhances the dentist's control over the manufacturing process.

3. Single Visit Restorations:

- CAD/CAM technology facilitates same-day restorations, allowing patients to receive crowns or veneers in a single dental visit.

- This streamlines the treatment process and enhances patient satisfaction.

4. Accuracy and Consistency:

- CAD/CAM ensures high precision and consistency in the production of dental restorations, minimizing errors and adjustments.

Integration and Synergy:

-

Comprehensive Workflows:

- Dental practices often integrate both 3D printing and CAD/CAM into their workflows for optimal results.

- CAD is employed for initial design, and 3D printing brings those designs to life with unmatched accuracy.

-

Treatment Planning:

- The combination of 3D printing and CAD/CAM allows for thorough treatment planning, from digital diagnostics to the final restoration.

The marriage of 3D printing and CAD/CAM technologies has ushered in a new era of precision and efficiency in dentistry. Whether crafting intricate prosthetics with 3D printing or designing precise restorations through CAD/CAM, dental professionals now have powerful tools at their disposal. The choice between 3D printing and CAD/CAM often depends on the specific requirements of a dental procedure, highlighting the importance of a comprehensive and integrated approach to dental technology. As these technologies continue to evolve, the future of dentistry promises even greater advancements in patient care and manufacturing processes.