In the dynamic world of 3D printing, advancements are continuously pushing the boundaries of what's possible. One area that's particularly exciting is the development of biocompatible resins, opening up a realm of possibilities in fields ranging from medicine to consumer products. In this post, we'll delve into the world of biocompatible resins, exploring their potential and applications.

Understanding Biocompatible Resins

Biocompatible resins are materials specifically engineered to be compatible with living tissues or organisms without causing harm. In the context of 3D printing, these resins enable the fabrication of objects or parts that can interact safely with biological systems. They are extensively tested to ensure they meet stringent safety and compatibility standards.

Applications in Medicine and Healthcare

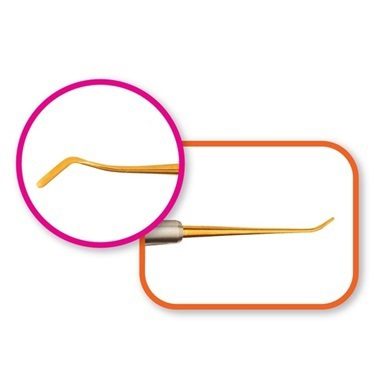

One of the most promising applications of biocompatible resins is in the medical field. These resins allow for the creation of custom implants, prosthetics, and medical devices tailored to individual patients. For example, surgeons can use 3D printing to produce patient-specific implants for orthopedic procedures, ensuring a perfect fit and optimal functionality. Biocompatible resins also play a crucial role in tissue engineering, where researchers aim to create functional tissues and organs for transplantation.

Advantages Over Traditional Materials

Biocompatible resins offer several advantages over traditional materials used in manufacturing. First and foremost, they provide greater flexibility and precision in design, allowing for intricate geometries and complex structures that are difficult or impossible to achieve with conventional methods. Additionally, 3D printing with biocompatible resins enables rapid prototyping and iteration, accelerating the development process for medical devices and implants.

Consumer Products and Beyond

Beyond the realm of medicine, biocompatible resins have the potential to revolutionize the production of consumer products. From biodegradable packaging materials to eco-friendly consumer goods, these resins offer a sustainable alternative to conventional plastics. Moreover, they open up new possibilities for creating personalized items such as jewelry, eyewear, and fashion accessories.

Challenges and Future Directions

While biocompatible resins hold immense promise, there are challenges that need to be addressed. Ensuring the long-term biocompatibility and safety of printed objects remains a priority, requiring rigorous testing and regulatory oversight. Additionally, further research is needed to expand the range of materials available and improve printing techniques for enhanced resolution and surface finish.

Looking ahead, the future of biocompatible resins in 3D printing is bright. As technology continues to evolve and our understanding of materials science deepens, we can expect to see even greater advancements in this field. From lifesaving medical innovations to sustainable consumer products, biocompatible resins are poised to make a profound impact on our world.